Building Deck-Railings Using Thread, Cyanoacrylate, and Railing-Jigs

The deck railings are

“thread-assemblies”; ie, they are made from thread

that is simultaneously glued together and hardened with cyanoacrylate

glue. Having good railings is crucial

for a good looking model so be sure to use this skill.

Since Deck Railings always have nice

right angles and straight runs, the easiest way to build them is to use a

“Railings-Jig”.

§

First, you need to make a jig:

I made mine

(rather roughly) from a 7-inch piece of 1X4 mahogany board. I cut out the middle with a jigsaw and

rounded all of the corners with sandpaper.

I drilled

four holes (in each corner) and drove metal pins through so that the pins stick

out about 3/8 inch on both sides. (I

used brazing rod for the pins.) These pins are used for tying off the thread

(and they are really handy to have).

You can see

three more L-shaped pins attached to the inside. These are used as attach points for making

rat-line-rigging for sailing ships.

§

In the plans, there is a

template for each deck railing.

§

Cut it out and temporarily glue

it to the edge of the jig.

§

Wrap thread around the width of

the jig so that the thread matches the railing posts on the template.

§

Next, wrap the thread round the

length of the jig to make the rails.

§

Tie off the thread.

§

Now, push and slide the thread

around so that the thread position matches the template.

Most

railings (as is the case with the Torrini) have two rails. But, as shown in the pictures, I always wind

a third "rail" at the bottom of each railing. This railing is cut away eventually. But in the meantime, it makes it possible to

cut the bottom of the posts to exactly the right length.

§

Next apply thin

cyanoacrylate glue to the assembly to glue the interstices together and to

harden the railings.

There

is a trick to avoid having the glue drop right though the jig: Hold a small strip of paper towel between the

dropper and the thread. Let it actually

rest on the thread. The drops are caught

by the strip of paper towel and are distributed to the thread.

§

Let the cyanoacrylate glue

dry.

§

Now check each interstice to

make sure that the threads are actually glued together. (There is the occasional miss). Re-glue such interstices with a toothpick

dipped in cyanoacrylate glue.

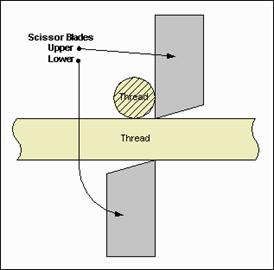

Now it is time to cut out the

railings. I use a small pair of sewing

scissors. There are four steps:

(This railing is

from the “Krakus”)

Here is the completed railing for the

boat-deck:

When doing the cutting, I find that

there is a particular way to place the railings against scissors that works

better.