Building Handrails and Rigging Using Thread, Cyanoacrylate, and Cardstock Templates

Using a Railing-Jig for holding your thread assemblies (while you harden them with Cyanoacrylate) works well for building railings. But when your thread assembly has lots of weird angles in it, the Railing-Jig doesn't work well. In this model, there are many thread assemblies that have odd angles:

§ The handrails for the six sets of stairs.

§ The rigging for the cargo derricks and lifeboat derrick..

I have been very successful in assembling these thread assemblies directly on printed cardstock templates. The cardstock templates do very well in holding the thread-assemblies in position while you harden them with cyanoacrylate.

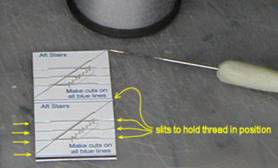

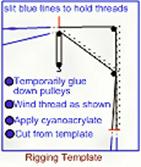

These cardstock-templates hold the thread in place by one or more of the following techniques:

t Slits are cut in the edges of the template and the thread is threaded through the slits. The slits hold the thread quite tightly.

t When the thread has to go around a pulley, you glue the pulley down to the template (I use white glue) and glue (white glue) the thread to the pulley (as you wind the thread around it). After the Cyanoacrylate is dry, the pulley is cut from the template still attached to the thread. Ie, the pulley becomes part of the thread assembly.

t When the thread must make a sharp bend, a secondary loop of thread can hold the thread in position at the bend-point. The loop of thread is held in position by running the two free ends through a slit cut in the edge of the template.

You might think that when the Cyanoacrylate is applied, that the thread assembly would become irremovably stuck to the template. It turns out that this is not the case as long as:

§ You need to use thin cyanoacrylate glue. Since cyanoacrylate glue gets thicker with age, be sure to use a relatively new bottle of thin cyanoacrylate glue.

§ You must blot up the excess cyanoacrylate glue with paper towels shortly after application

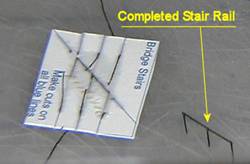

You will still have to carefully cut (pry) the thread assembly loose from the template with your Exacto-knife. But it is not that difficult.

Before cutting/prying the thread assembly loose, be sure to:

§ Check for and re-glue any interstices that did not get glued together properly.

§

Trim off the extra portions of the thread

assembly.

What Kind of Thread?

I like silk thread the best. It is strong, takes cyanoacrylate glue well, and does not have any "fuzz".

Second choice is 100% cotton thread. It takes cyanoacrylate glue fairly well, but there is some "fuzz".

I don't like Polyester or cotton covered Polyester.

But experiment around; you might arrive at different conclusions.